How Is Luwak Coffee Made: The Art Behind the Brew

January 22, 2026 • 7 min read

- Production of luwak coffee involves unique biological and chemical transformations during the civet digestion process.

- The quality and characteristics of luwak coffee are highly dependent on the animal's diet, processing methods, and geographical origin.

- Ethical considerations and sustainability challenges significantly impact industry practices and consumer perception.

- Advanced analytical techniques provide insights into the compositional changes and sensory attributes resulting from digestion and fermentation.

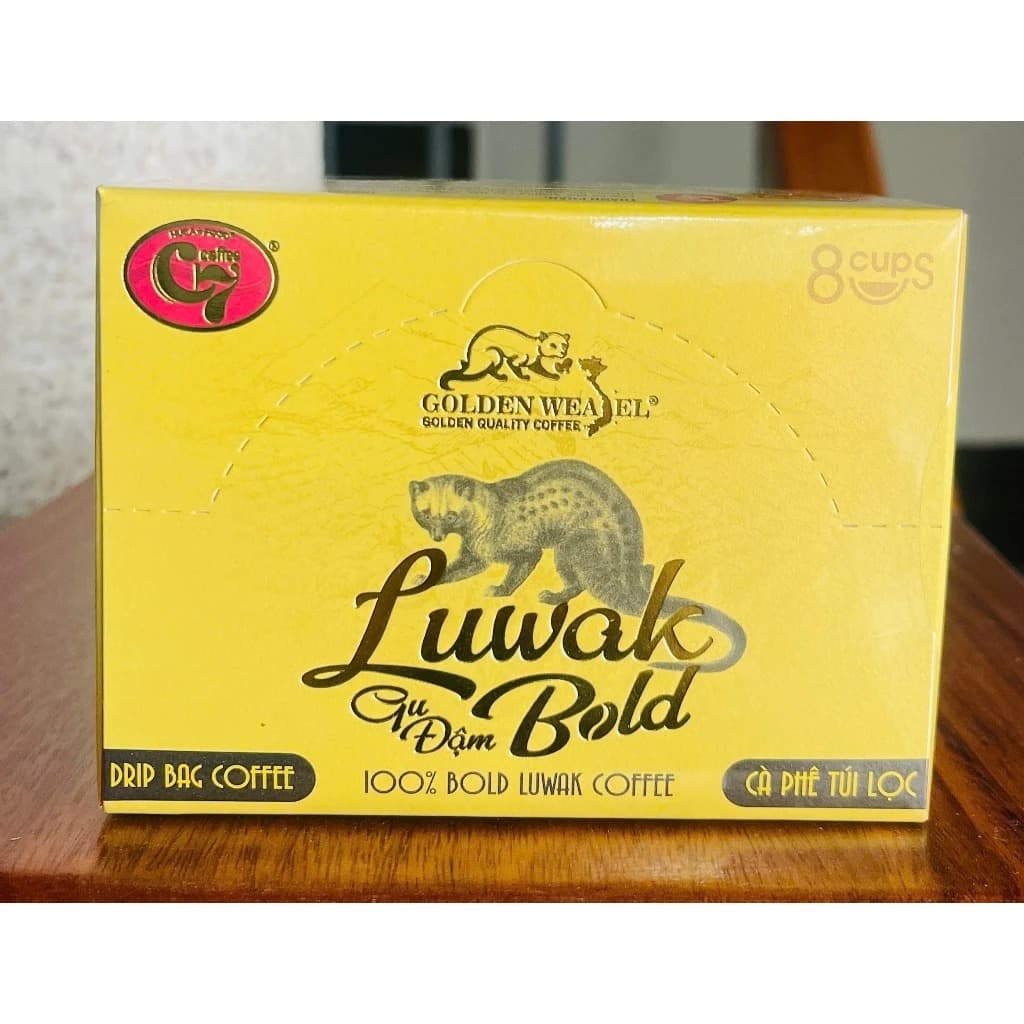

The production of luwak coffee is a complex interplay of biological digestion, enzymatic alteration, and post-harvest processing that yields a distinctive final product. This rare coffee, derived from beans consumed and excreted by the Asian palm civet (Paradoxurus hermaphroditus), combines natural enzymatic treatment with traditional coffee processing. Understanding how luwak coffee is made requires an examination of the civet's physiology, the biochemical modifications occurring within the digestive tract, and the subsequent handling of the coffee beans after recovery. The scientific analysis of these steps elucidates why luwak coffee possesses unique flavor profiles and what factors influence its quality and authenticity. The following editorial presents a detailed, technical overview of the entire production sequence from bean selection to final roasting.

Biological and Chemical Mechanisms Behind Luwak Coffee Production

The Role of the Asian Palm Civet in Coffee Processing

The Asian palm civet is a small carnivorous mammal native to Southeast Asia, renowned for its selective frugivorous behavior, where ripe coffee cherries constitute a significant part of its diet in the wild. The civet's digestive system plays a pivotal role in modifying the coffee cherries before bean extraction. As the cherries pass through the gastrointestinal tract, the outer pulp and mucilage layers are enzymatically and microbiologically degraded. The civet's digestive enzymes, including proteases and carbohydrases, partially break down the proteins and polysaccharides present in the coffee mucilage. This fermentation-like process alters the chemical composition of the silver skin and endosperm of the coffee bean. Subsequent defecation naturally expels the partially digested beans intact, albeit freed from most pulp residues. The selective feeding behavior, combined with the unique digestive biochemistry, creates the foundational changes that differentiate luwak coffee from conventionally processed counterparts.

Biochemical Transformations During Digestion

The digestive process inside the civet effectuates both proteolytic and fermentative modifications. Proteolytic enzymes degrade specific coffee bean proteins, potentially reducing bitterness and astringency through altering precursor compounds. Concurrently, endogenous and gut microbiota contribute to fermenting sugars and other compounds within the mucilage layer, generating secondary metabolites that influence flavor precursors. Studies employing chromatographic and spectroscopic techniques have revealed reductions in chlorogenic acid content and alterations in volatile aromatic compounds due to lignin and polyphenol metabolism. Additionally, changes in pH and temperature within the civet's gut affect enzymatic activity rates and metabolite formation, collectively influencing bean chemistry. These transformations create a bean matrix with reduced acidity and an enhanced profile of aroma compounds post-fermentation, setting the stage for distinctive sensory attributes upon roasting.

Post-Digestion Processing: From Bean Recovery to Roasting

Collection and Cleaning of Luwak Coffee Beans

Following excretion, the luwak coffee beans are collected manually, which presents inherent challenges related to purity, yield, and ethical sourcing. The beans require meticulous washing to remove residual fecal matter without damaging the delicate seed coat. The cleaning process typically involves multiple stages of rinsing in clean water, sometimes combined with gentle scrubbing and drying under sun or controlled conditions. High-quality luwak coffee production standards mandate stringent hygiene protocols to prevent microbial contamination and ensure food safety compliance. The drying phase is critical; improper drying can induce mold growth or prematurely degrade aromatic compounds. Verified harvests employ temperature-monitored drying platforms, maintaining bean moisture content below 12%, optimizing storage stability and sensory integrity.

Drying, Roasting, and Quality Control Measures

After cleaning, beans undergo drying which stabilizes biochemical changes induced by digestion and prevents undesirable fermentations. Post-drying, the green coffee beans are roasted, a thermochemical process wherein Maillard reactions, caramelization, and pyrolysis develop the final flavor profile. For luwak coffee, roasting parameters tend to be optimized based on the reduced acidity and modified sugar-protein matrix to accentuate its mildness and unique sensory signatures. Analytical techniques like gas chromatography-mass spectrometry (GC-MS) confirm the development of volatile compounds such as furans, aldehydes, and pyrazines, which contribute to aroma and taste complexity. Quality control further involves sensory evaluation panels and chemical fingerprinting to detect adulteration, given the prevalence of counterfeit products in the market. Traceability protocols and DNA barcoding have emerged as advanced tools for authenticity verification within the industry.

Industry Dynamics and Ethical Implications

Wild Harvesting Versus Captive Production Systems

The commercial supply of luwak coffee bifurcates into wild-harvested and farm-raised production models, each manifesting distinct ethical and sustainability considerations. Wild-harvested beans are collected from forest habitats where civets forage naturally, resulting in sporadic yield and ecological balance. Conversely, captive production often involves caged civets subjected to controlled feeding regimens to maximize output. The latter raises significant animal welfare concerns, including malnutrition, stress, and unnatural behaviors. From an industry perspective, sustainable wild-harvesting methods are preferable, preserving native biodiversity and aligning with conservation ethics. However, scalability challenges and supply inconsistencies necessitate ongoing dialogue around certification standards and regulatory oversight to mitigate cruelty while securing product authenticity.

Environmental and Economic Considerations

Environmental sustainability in luwak coffee production encompasses aspects such as habitat preservation, biodiversity maintenance, and resource management across supply chains. The encroachment of coffee plantations on ecologically sensitive areas for cultivation affects the civet's natural foraging dynamics, potentially altering coffee quality and availability. Economically, luwak coffee commands premium pricing driven by scarcity, unique production methods, and market demand. This premium incentivizes counterfeit products and unethical farming practices, undermining legitimate producers. Balancing economic growth with ethical production requires multi-stakeholder involvement, including industry associations, regulators, conservation bodies, and consumers. Transparency initiatives like traceability frameworks and eco-labeling can promote responsible sourcing and support local communities dependent on the wild-harvested bean trade.

Expert Analysis & FAQ

What biochemical changes in the civet's gut most significantly affect the coffee bean's flavor profile?

The most consequential biochemical changes include proteolytic enzyme activity, which reduces certain protein-derived bitter compounds, and microbial fermentation altering polysaccharides within the mucilage. These processes decrease acidity and modify volatile precursor compounds such as chlorogenic acids and polyphenols, leading to a smoother cup profile with attenuated bitterness and complex aroma development.

How do production methods impact the authenticity and quality of luwak coffee?

Production methods, particularly the distinction between wild-harvesting and captive farming, significantly affect both quality and authenticity. Wild-harvested beans reflect natural dietary variety and digestion, producing characteristic flavor nuances. Captive farming often employs standardized feeding regimes, sometimes using low-quality cherries, leading to diminished sensory attributes. Furthermore, adulteration arises when external beans are falsely marketed as luwak coffee, necessitating robust analytical verification methods to ensure product integrity.

What are the primary ethical challenges associated with luwak coffee production, and how does the industry address them?

Ethical challenges include animal welfare concerns related to captive civet farming, such as confinement stress and improper nutrition. Environmental issues involve habitat disruption from coffee cultivation expansion. Industry responses include promotion of wild-harvested luwak coffee, implementation of certification schemes emphasizing humane practices, and advocacy for sustainable agricultural systems that protect civet habitats while maintaining product quality and consumer transparency.

Can advanced scientific techniques reliably differentiate authentic luwak coffee from counterfeit products?

Yes. Techniques such as DNA barcoding, isotope ratio mass spectrometry, and metabolomic fingerprinting provide molecular-level data distinguishing genuine luwak coffee beans from common coffee bean adulterants. These methods identify specific genetic markers and biochemical profiles altered by civet digestion that are absent in conventional beans, enhancing detection capacity and ensuring supply chain authenticity.

-01K3MNQFWTSA5G4M5PFD03K4EV.png&w=1920&q=75)

-01KEE3GHXK9VD75BM513FCHP6Q.jpeg&w=1920&q=75)

-01K3MRPG09NNHHJB7EQ406RG5P.png&w=1920&q=75)

-01KBDBXBZ38H4QE54X80WTK7Q6.png&w=1920&q=75)

-01K3N2MK9AHNGTW6V4RBKGM3Y1.png&w=1920&q=75)